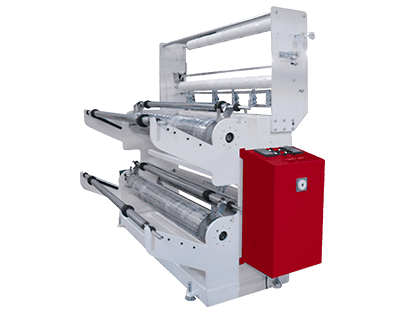

Blown Film Winder

Extrusion Blown Film Winder is the last process of Plastic Film Blowing Machine to produce plastic film products. To maintain the tension of film and make it easy to use for post-processing, the role of Extrusion Winder in Plastic Blown Film Line is extremely significant. Ensure the film which came from the Take-Up Unit is flat type and the final step should keep the film stably without any uneven. Film Winder. Further, the line speed (take-up speed) is the primary device to control the film thickness and the stability of film as well.

For those customers with spaces problems, the Double Vertical Film Winder will be the best choice since the volume of it does not take up space. Due to the special design, the up-side and down-side rollers are parted so the Double Vertical Film Windier cannot bear too heavy for the up-side roller. As a result, it often uses for products with volume that not large.

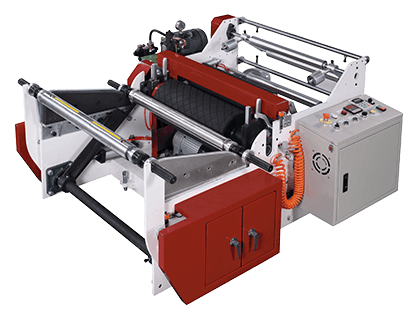

Back to Back Blown Film Winder is constitute with two stations that back to each other. Typically, it combines two winding stations with familiar machine functions into a complete set. With the various function, it produces both single layer and two-layers film. Besides, the machine is available to divide into two bodies for independent working according to the requirements of customer as well.

The classic Manual Blown Film Winder is the basic and most economical type. For the use of manual type, it is more suitable for film width which is not that wide since it needs to use manual operation. Also, it is divided to Single and Double Manual Blown Film Winder for different requirements.