The Production facility of ETERLONG is fully equipped with a wide range of sophisticated machining equipment including 5-Axis Bridge Milling, CNC Lathe, CNC Milling, Radial Drilling Machine and 3-Axis Grinding Machine. With the ability of 95% made in house and the outstanding self-machining capability allows us to completely control the parts accuracy and increase production efficiency.

5-Axis Bridge Milling Machine, CNC Lathe Machine and CNC Milling Machine

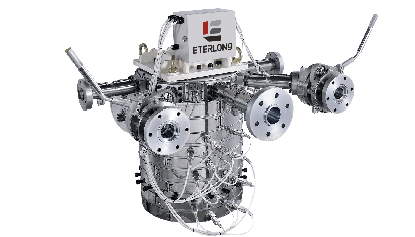

Based on superior rigidity structure combined with powerful spindle output and well featured key components to accomplish and achieve outstanding heavy cutting capability. All of path for milling, drilling, thread rolling, slanting hole drilling and tapping are controlled by computer program to ensure the accuracy and tolerance of Die Heads and collocate with auto tool presetter which arm is rotated automatically by programming. Special clamping system to release up and vertical down, and automatically forward to drill the set up depth by pushing the button switch and collocate with auto tool withdrawing unit. Positioning lock by bolts to make every hole to be precise, accurate and steady.

Germany 3-Axis Grinding Machine

Ram Type Surface Grinder with Rotary Table to grind internal circle, external circle, surface and bottom face and to make the Die Head stay in accuracy before assembly.

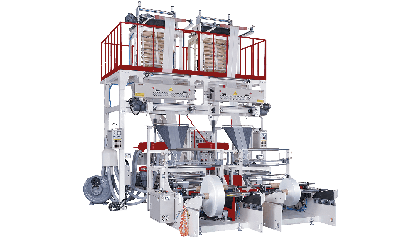

ETERLONG has a wide range of products from small components to large-sized work, regular Mono Layer Die Heads, ABA Die Head to tailor-make Multi-Layer Die Head, we can all self-machined in house. As a result, ETERLONG products are extremely competitive in terms of accuracy, quality and delivery time.

Precision Manufacturing

| Name | own | Name | own |

|---|---|---|---|

| Height Gauge | ● | Inside Micrometer | ● |

| Outside Micrometer | ● | Vernier Caliper | ● |

| Roughness Tester | ● | Equotip Hardness Tester | ● |

| Coating Thickness Gauge | ● | Gauge Block | ● |

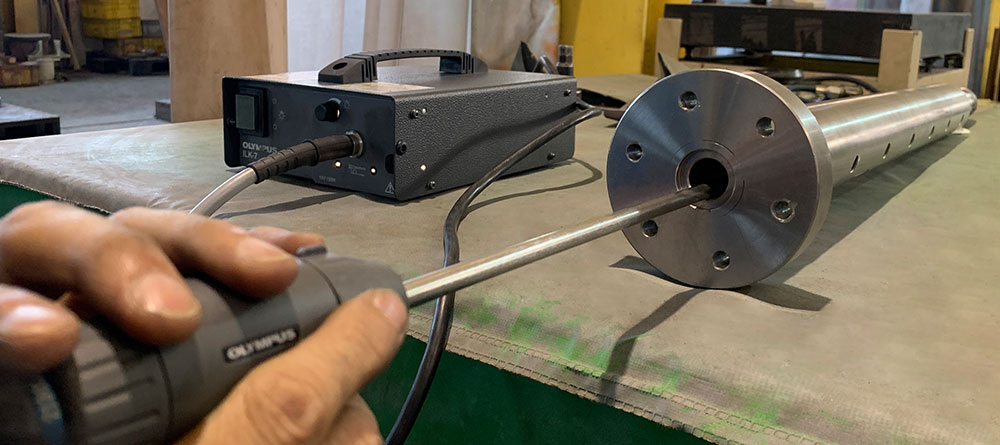

| Depth Gauge | ● | Industrial Endoscope | ● |

| Precision Mica Platform | ● |