How does the Blown Film Industry Change?

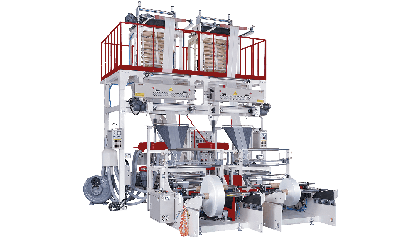

The application of the plastic film has changed since the plastic restriction policy changed, environment awareness raised up and different raw materials used. From the shopping bags and garbage bags to the recent use of barrier film, the types of blown film extrusion machine and the matching extruder die head has changed.

The types of blown film extrusion die head are getting various from the basic single layer to the functional multi-layers. As the different lifestyle and the unpredictable event, the habit of plastic products has changed. As a result, the blown film industry start searching the new industrial type to fit in the new trend.

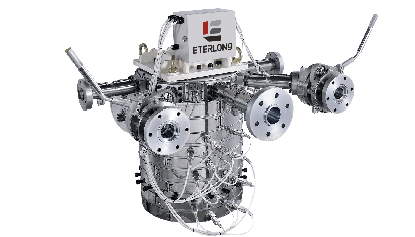

Eterlong's multi-layers die is able to help the film creates its maximum effect on the product. By using different materials, it improves the functional features of film such as barrier properties, freshness, moisture, front resistance, insulation, oxygen resistant, oil resistant, and etc. Depends on different product request, customer is available to choose the material and additives to satisfy their needs.

FEATURES:

- Save Material Costs

- Maintain Product Quality

- Reduce Artificial Additives

- Keep Product Quality

- Prevent Pollution

- Increase Product Value

- Convenience for Consumers

STRUCTURES & PROPERTIES

Mention about the blown film die head, the types of die head will base on the final producing film layers. The multi-layers type is available to use several materials to produce the plastic films with various function and well performance. The structure of multi-layers film is more complicated but includes several functions with different materials in each layer to enhance the properties of film. By the specific design and the mold flow analysis, Eterlong's multi-layers die is able to produce films with high-level improved qualities. Further, to increase the functional advantages, it allows to add many kinds of additives such as water-proof, anti-UV, stabilizer, recycled material and so on. With these additives, the film equipped with multi-functions brings a wide range of advantages that improve the film quality and work efficiency.

PROPERTIES:

- Barrier Properties

- Freshness

- Moisture Retention

- Front Resistant

- Insulation Property

- Oxygen Resistant

- Oil Resistant

EXPERIENCES & SERVICE

Since blown film multi-layers extrusion die head is a more complicated and precision product, Eterlong will confirm the specification clear in order to collocate the suitable machine for customers. Depending on the experiences, the choice of product will be different as well. As the consultant of extrusion products, Eterlong has rich experiences to support and offer the customized advice and specific evaluation as well. In order to establish the trust with customers, Eterlong not only create high quality products but also provide full range of customer service.

Before moving into all the production process, Eterlong will take full discussion of the specification with customers. Take the seven layers extruder for example, the discussion with the complete information includes screw size, use material, film thickness, and material ratio. All the specifications will help to choose the suitable collocation for customers.

| EXTRUDER | Screw Size | Use Material | Film Thickness | Material Ratio |

|---|---|---|---|---|

| A | #40 | LDPE | 25 - 30% | 14 μm |

| B | #40 | TIE | 5 - 8% | 5 μm |

| C | #40 | PA | 10 - 14% | 8 μm |

| D | #40 | EVOH | 8 - 10% | 6 μm |

| E | #40 | PA | 10 - 14% | 8 μm |

| F | #40 | TIE | 5 - 8% | 5 μm |

| G | #40 | LDPE | 25 - 30% | 14 μm |

K SHOW 2022, one of the biggest exhibitions of Plastics & Rubber Industry will be held from 19th - 26th October at Düsseldorf, Germany. Eterlong, specialize in blown film die head, is going to join this grand event to meet the old friends and new acquaintances as well. If you want to know how to select your ideal die head or to get more information from us, we sincerely welcome you to visit Eterlong.

▶ Booth No. Hall 12 A02-04.

Source : PRM E-News Issue 220