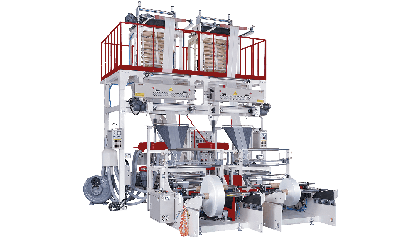

Multi-Layers Blown Films market is expected to increase in the next few years. First, let’s give a brief talk about the Blown Film Extrusion Die Head. Mention about the Blown Film Extrusion Die Head, the types of die head will base on the final products. The Multi-layers Blown Film Extrusion Machine is available using different materials to produce the plastic films with various functions and well performance. Due to manufacturing the multi-layers film, the whole industry of Blown Film Extrusion Machine becomes more complicated and more precise than before. As you can see the list as below, the properties of the multi-layers film:

- Barrier Properties

- Freshness

- Moisture Retention

- Front Resistant

- Insulation Property

- Oxygen Resistant

- Oil Resistant

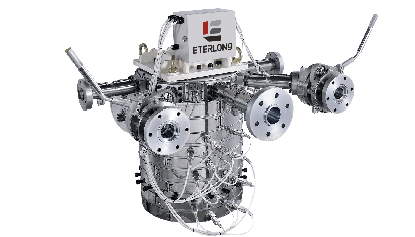

By the specific design and the mold flow analysis, Eterlong's Multi-Layers Blown Film Extrusion Die Head produces the film which increases its own value. In order to achieve the above properties and to be more functionable, Eterlong can customize the Blown Film Extruder Die Head and allows to selectively add more additives such as water-proof, anti-UV stabilizer, recycled material and so on. With these additional materials, the film equipped with multi-functions brings a wide range of advantages that improve the film values and work efficiency.

Since Multi-Layers Blown Film Extrusion Die Head is a more complicated and precision product, Eterlong will confirm the specification carefully in order to collocate the suitable machine for customers. Depending on the experiences, the choice of product will be different as well. As the consultant of extrusion products, Eterlong has rich experiences to support and offer the customized advice and specific evaluation as well. In order to establish the trust with customers, Eterlong not only creates high quality products but also provide full range of customer service.

For different customers, we have different advices. Eterlong confirms every specification with all the customers before moving into the production process. After conferring with the customers of their materials and ratios, Eterlong end up with a full success decision for them. As you can see the below seven layers extruder for example, all the specifications after discussion became the suitable collocation for customers.

| EXTRUDER | Screw Size | Use Material | Film Thickness | Material Ratio |

|---|---|---|---|---|

| A | #40 | LDPE | 25 - 30% | 14 μm |

| B | #40 | TIE | 5 - 8% | 5 μm |

| C | #40 | PA | 10 - 14% | 8 μm |

| D | #40 | EVOH | 8 - 10% | 6 μm |

| E | #40 | PA | 10 - 14% | 8 μm |

| F | #40 | TIE | 5 - 8% | 5 μm |

| G | #40 | LDPE | 25 - 30% | 14 μm |

K SHOW 2022 will be held from 19th - 26th October at Düsseldorf, Germany. Eterlong, specialize in Blown Film Extrusion Die Head, is going to join this grand event and expecting to meet the old friends and new acquaintances as well. If you want to know how to select your ideal Die Head or to get more information about the Blown Film Extrusion Machine, we sincerely welcome you to visit Eterlong.

IN OTHER NEWS

All the latest News about ETERLONG

Exhibition Message

Chinaplas 2025

Venue:Shenzhen World Exhibition & Convention Center (Bao'an), PR China

Date: April 15 - 18, 2025

Booth No.:7W11

Read More

Exhibition Message

PLAST EURASIA ISTANBUL 2024

Venue:Tüyap Fair Convention and Congress Center

Date: December 04 - 07, 2024

Booth No.:#10 1014D

Read More