ABOUT ETERLONG

Eterlong Co., Ltd., located in Tainan, southern Taiwan, has long been engaged in custom manufacturing of semiconductor industry machine components, sheet metal forming processing, and automation control system integration. With extensive expertise in metal processing and high-precision machinery, Eterlong has earned high praise from our customers.

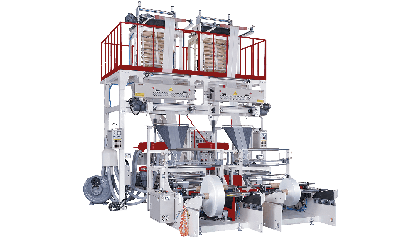

In April 2023, Eterlong merged with Hsin Long Company, a well-known manufacturer with over 50 years of experience specializing in the production of blown film machines and related components. Eterlong aims to provide more comprehensive services to our customers.

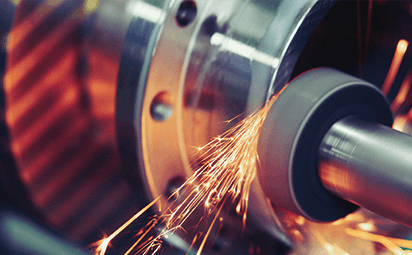

Eterlong boasts precision CNC gantry milling machines, lathes, grinding equipment, as well as Germany's Trumpf large-scale computerized bending machines, 4000W high-power laser cutting machine, Germany KUKA 2000W laser welding robot, horizontal vacuum hard soldering, and vacuum heat treatment, among other mechanical processing equipment. The wide, bright, and modern factory, along with a team of skilled designers, developers, production manufacturers, and warehouse managers, vividly demonstrates a strong determination to achieve a thriving ambition for high-quality and high-performance automation features in blown film machine units.

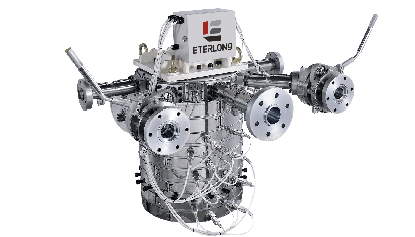

Our brand, ![]() , is adopted to symbolize a sustainable business operation, to motivate us to in continuous research and development for blown film machine units and die design and processes. Meanwhile, we aim to meet customer demands for high-quality, highly efficient production and adhere to the philosophy of uninterrupted service. We pay close attention to the craftsmanship details in each metal processing step, striving to create products with exceptional functionality and a sense of metal aesthetics to fulfill customer needs and provide comprehensive solutions for complex plastic film molding issues.

, is adopted to symbolize a sustainable business operation, to motivate us to in continuous research and development for blown film machine units and die design and processes. Meanwhile, we aim to meet customer demands for high-quality, highly efficient production and adhere to the philosophy of uninterrupted service. We pay close attention to the craftsmanship details in each metal processing step, striving to create products with exceptional functionality and a sense of metal aesthetics to fulfill customer needs and provide comprehensive solutions for complex plastic film molding issues.

In the era of continuous technological innovation, the ![]() brand of blown film machines and die heads continues to challenge quality optimization and market differentiation. Equipped with the most advanced equipment and mold flow analysis software, we deliver tangible optimization of plastic co-extrusion machines and die components, along with virtual test simulations, to achieve our customers' higher production efficiency goals.

brand of blown film machines and die heads continues to challenge quality optimization and market differentiation. Equipped with the most advanced equipment and mold flow analysis software, we deliver tangible optimization of plastic co-extrusion machines and die components, along with virtual test simulations, to achieve our customers' higher production efficiency goals.

Eterlong firmly believes that dedicated pursuit of craftsmanship excellence and a focus on perfect details are our growth foundations. Through the integration of brand and technology, we aspire to be the professional leading force in the blown film market, collaborating with industry peers for the blown film industry prosperity.

OUR RELATIONSHIP PARTNERS

THANK YOU FOR YOUR INTEREST IN ETERLONG—WE ARE PLEASED TO BE AT YOUR SERVICE!

Eterlong Co., Ltd. Japan branch office

TOMITA CHEMITECH CO., LTD

2-110, 6-CHOME, SHIMOKATA CHO, CHIKUSAKU, NAGOYA CITY, AICHI PREF., 464-0096, JAPAN

052-700-1469 / 070-8538-8799

tmct@eterlong.com

Our services:

Extrusion precision die manufacturing, film blowing machinery manufacturing equipment, titanium alloy processing, chemical machinery and equipment, metal processing products, chemical industrial pharmaceutical raw materials, household electrochemical products, coatings, dyes, pharmaceutical quasi-drugs, food additives, feed additives Trade, wholesale, brokerage, and agency business related to chemicals, fertilizers, agricultural materials, etc.

Eterlong Co., Ltd. - Affiliated Companies

YING CHANG TECHNOLOGY INDUSTRY CO., LTD.

NO.30, GONGYE 5TH RD., ANNAN DIST., TAINAN CITY 709-015, TAIWAN(R.O.C.)

+886-6-384-0198

gchuang@advanti.com.tw

Our services:

We supply Copper Sulfate, Copper Powder, Sodium Thiosulfate, Ammonium Sulfate (Produced by TSMC) and Water treatment disinfectant. We are also circular economy chemical manufacturer, providing customized chemical products services abroad

Professionalism

More than

50

years

Productivity

Sell more than

1,000

sets Die Head

Sales Status

Sell more than

70,000

sets Die Head around the world

Customers

Own more than

1,500

customers

Globally

More than

85

countries around the world

Concept & Advantages

Passion for metal processing and blown film machinery, coupled with technological mastery for innovative solutions.

Continuously advancing mold flow technology to meet customers products’ functional requirements, offering optimized configurations, and virtual test simulations for a more efficient production.

Innovation in R&D, meticulous process examination, and proactive customer care for a complete user experience.