Eterlong is dedicated to providing the most advanced mold flow analysis technology, particularly using the Virtual Extrusion Laboratory (VEL) software developed by Compuplast®. By combining the experience of multiple experts in the plastics field, we can accurately simulate various extrusion processes.

Eterlong possesses advanced equipment and technology, enabling optimal configuration for plastic co-extrusion machines and dies, and providing virtual trial mold simulation results. This helps customers improve production efficiency and reduce development costs. Our mold flow analysis technology not only predicts potential issues in the process but also provides specific solutions to ensure product quality and production stability.

Eterlong always focuses on customer needs, pursuing technological innovation and excellence in quality, striving to become a leader in the blown film machine processing field and a trusted partner for customers.

Advantages:

- Accurate Simulation:VEL software can accurately simulate various extrusion processes, predict potential issues in the process, and provide specific solutions to ensure product quality and production stability.

- Efficiency Improvement:Through virtual trial mold simulation results, Eterlong Precision can help customers optimize equipment configuration, improve production efficiency, and reduce development costs.

- Technological Innovation:Eterlong Precision always centers on technological innovation, combining the experience of multiple experts in the plastics field to provide advanced mold flow analysis services, meeting the diverse needs of customers.

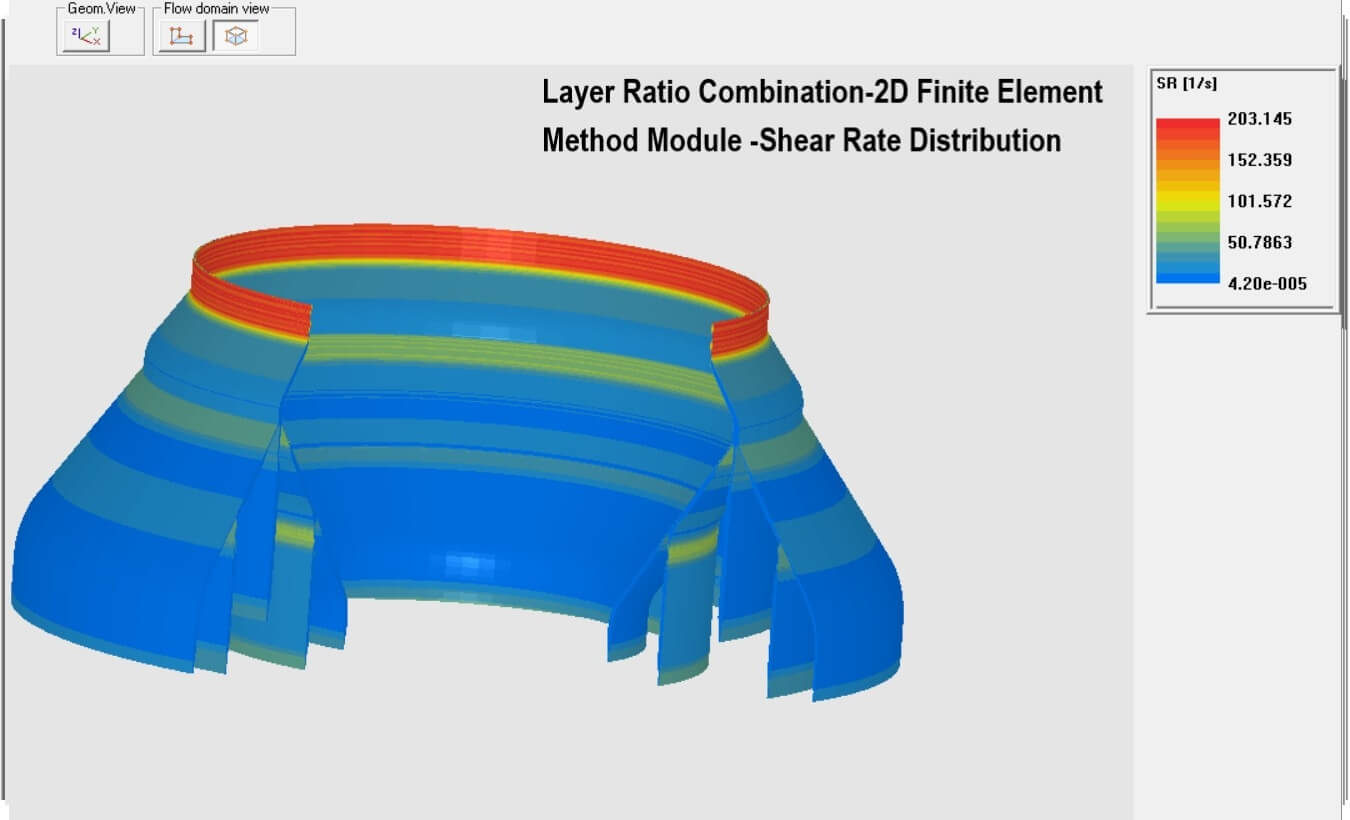

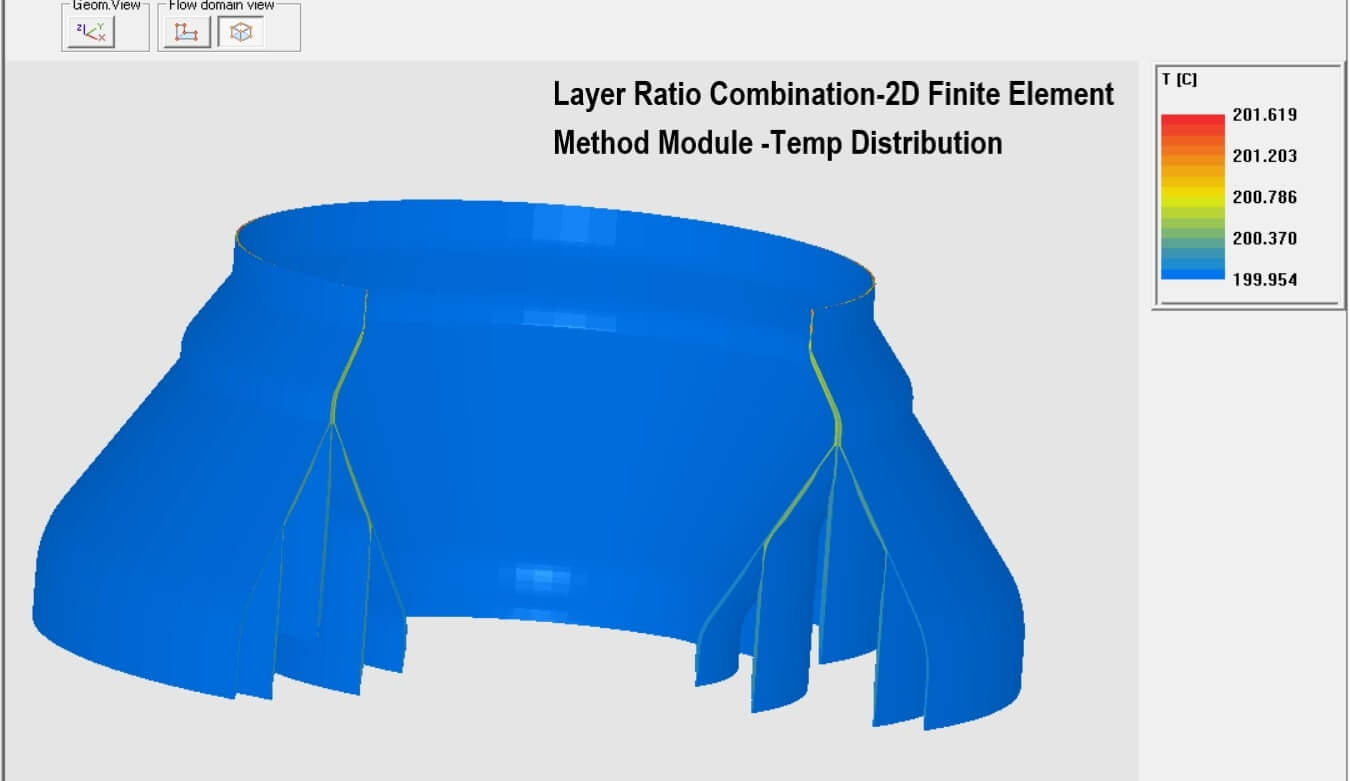

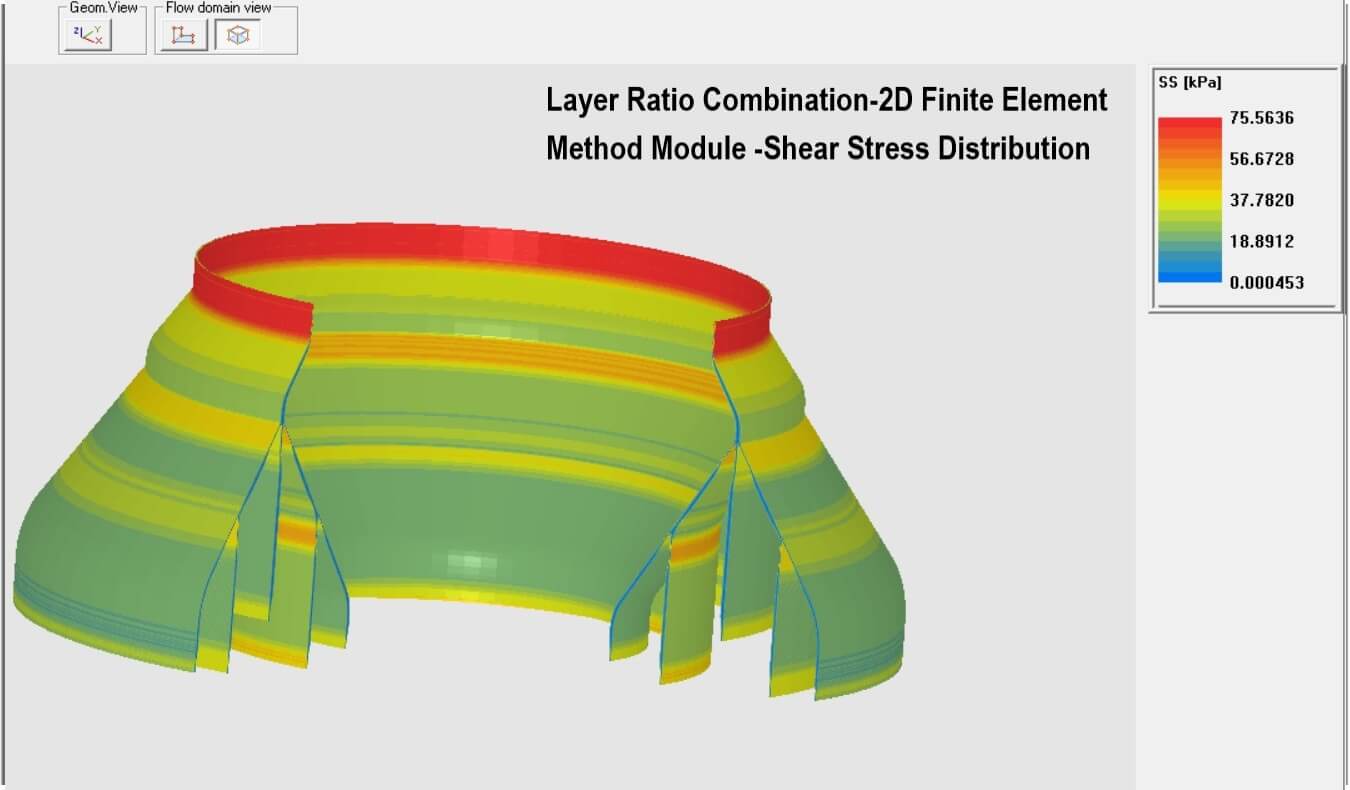

Make good use of the 2D Finite Element Method (FEM) in mold flow analysis to simulate and predict the flow behavior of plastics within the mold.

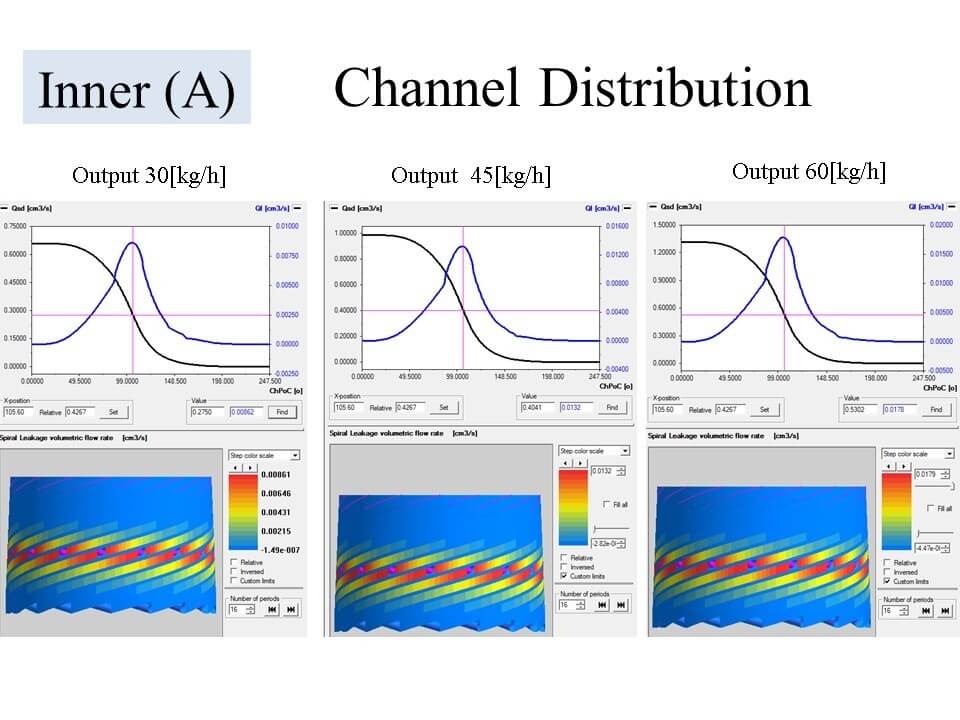

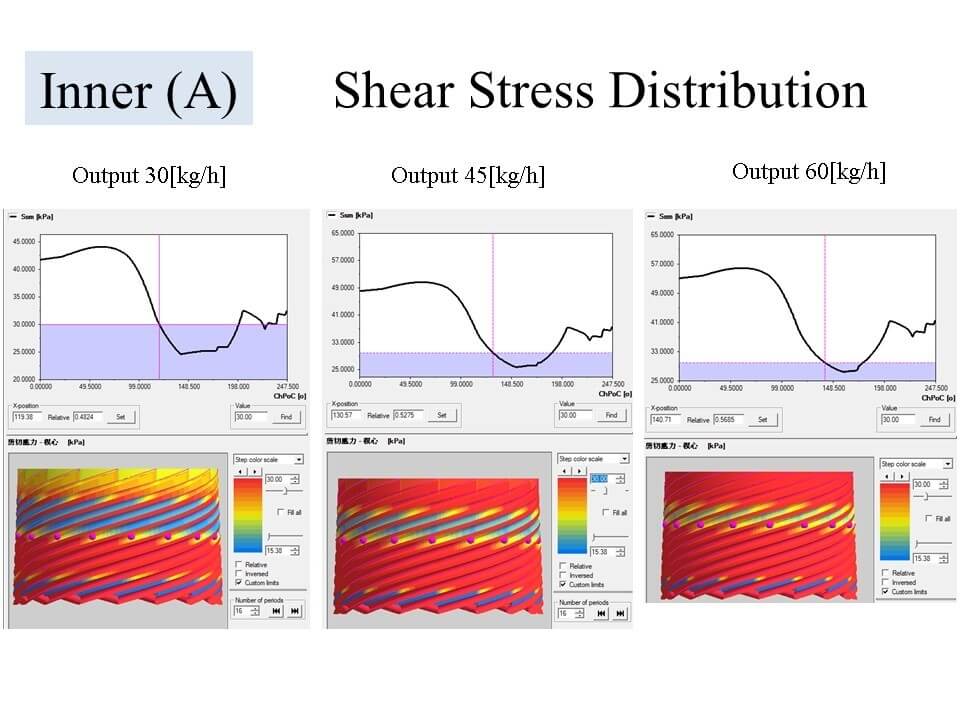

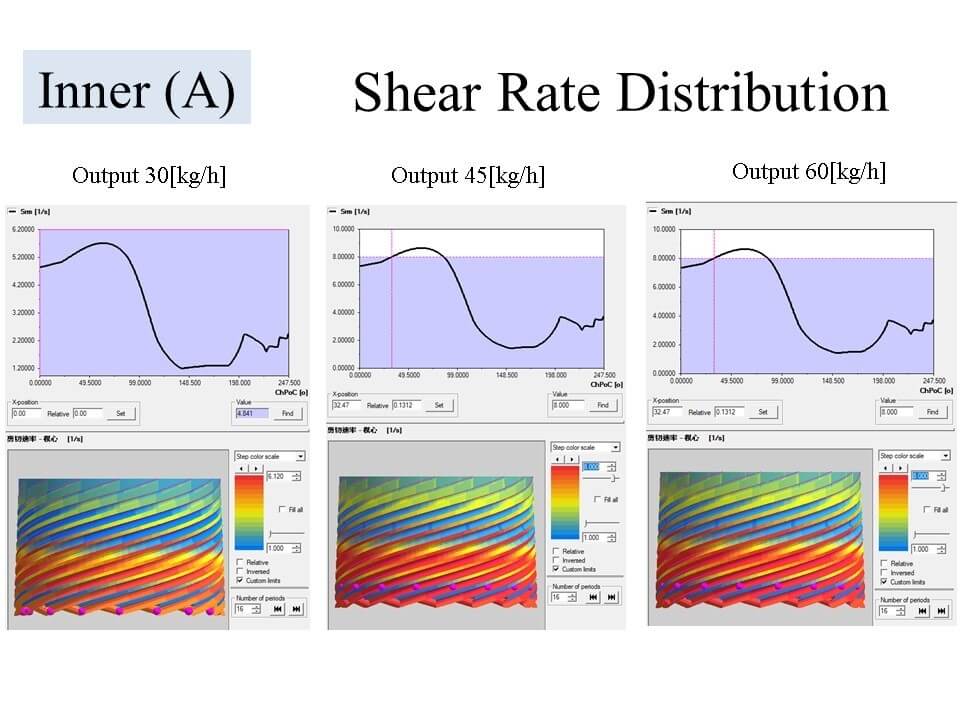

The functions of the spiral distribution section

- Uniform Mixing of Melt

- Reduction of Pressure Loss

- Control of Shear Stress

- Uniform Distribution of Melt

Advantages:

• Pressure Distribution Analysis:Through mold flow analysis, the pressure changes in the distribution section can be simulated and calculated to ensure that pressure loss is within a reasonable range, preventing product defects.

• Temperature Distribution Analysis:Analyzing the temperature distribution of the melt in the distribution section ensures that the melt enters the mold cavity at a consistent temperature, avoiding molding defects due to temperature differences.

• Flow Behavior Analysis:Simulating the flow behavior of the melt in the distribution section to identify issues such as stagnation zones, vortices, or uneven flow.

By conducting mold flow analysis of the spiral distribution section, screw design and process parameters can be optimized to improve melt uniformity and the quality of the final product.